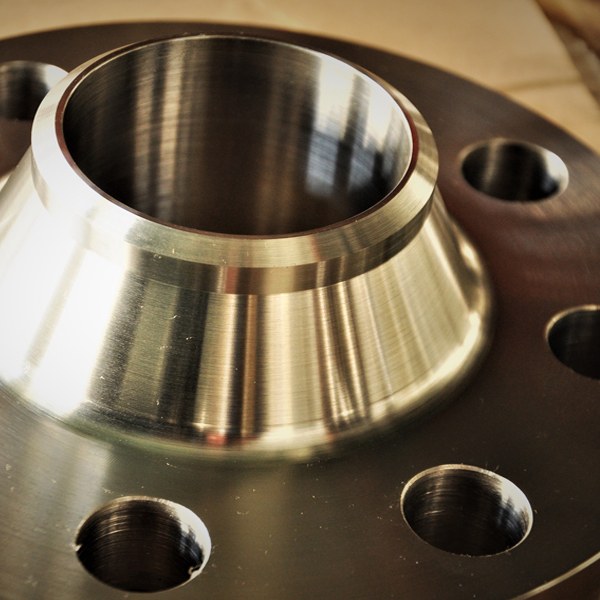

A flange is a flat, circular (or sometimes ring-shaped) mechanical component used to connect two sections of pipe, conduit or equipment in a watertight manner. Flanges are designed to allow system components to be assembled and disassembled, making it easier to maintain, repair or replace parts. Flanges generally have holes drilled at regular intervals around their circumference. These holes are used to align and secure the flange in place using bolts, nuts and washers. When two flanges are joined, they are held together by the bolts, creating a strong, watertight connection. Gaskets, such as rubber gaskets, O-rings or metal gaskets, are often placed between the flange faces to ensure a perfect seal and prevent leakage. WN / SW / Pleine / Slip-onSlip On Flange ASME B16.5 / EN1759-1 / 1/2″ - 24″Slip On Flange ASME B16.5 / EN1759-1 / 1/2″ - 24″Lap Joint Flange ASME B16.5 / EN1759-1 / 1/2″ - 24″Full Flange ASME B16.5 / EN1759-1 / 1/2″ - 24″SW Flange ASME B16.5 / EN1759-1 / 1/2″ - 24″Screw flange ASME B16.5 / EN1759-1 / 1/2″ - 24″Slip on flange BS3293 / 26″ - 48″Slip on flange BS 3293 / 26″ - 48″Slip on flange ASME B16.47 Series A - MSS SP-44 / 12″ - 60″Flanged flange ASME B16.47 Series B - API STD 605 / 12″ - 60″Full flange ASME B16.47 Series A - MSS SP-44 / 12″ - 60″Full flange ASME B16.47 Series B - API STD 605 / 12″ - 60″Long flange ASME B16.5 / EN1759-1 / 1/2″ - 24″Reducing flange ASME B16.5 / EN1759-1Orifice flange ASME B16.36Carbon steel to ASTM A105Stainless steels to ASTM A182Alloy/low temperature steels to ASTM A350."